Metryva MTVTB Series Double-Offset & Triple-Offset Butterfly Valves – Maximum Performance in Demanding Conditions

Durable, low-torque, zero-leakage valves for industrial, high-pressure, and temperature-critical environments.

Double-Offset Valve Highlights

Bi‑Directional Double‑Offset Design with PTFE seats enables smooth operation and maintenance via API 609 compliance.

Size & Rating Range: 2"–160" (DN50–DN4000), ASME Class 150–600.

High Material Variety: Carbon, stainless, alloy, and copper steel available.

Flexible End Connections & Operation: Wafer, lug, RF; lever, gear, pneumatic, electric, hydraulic.

Design Advantages: Low operating torque, compact and lightweight yet robust.

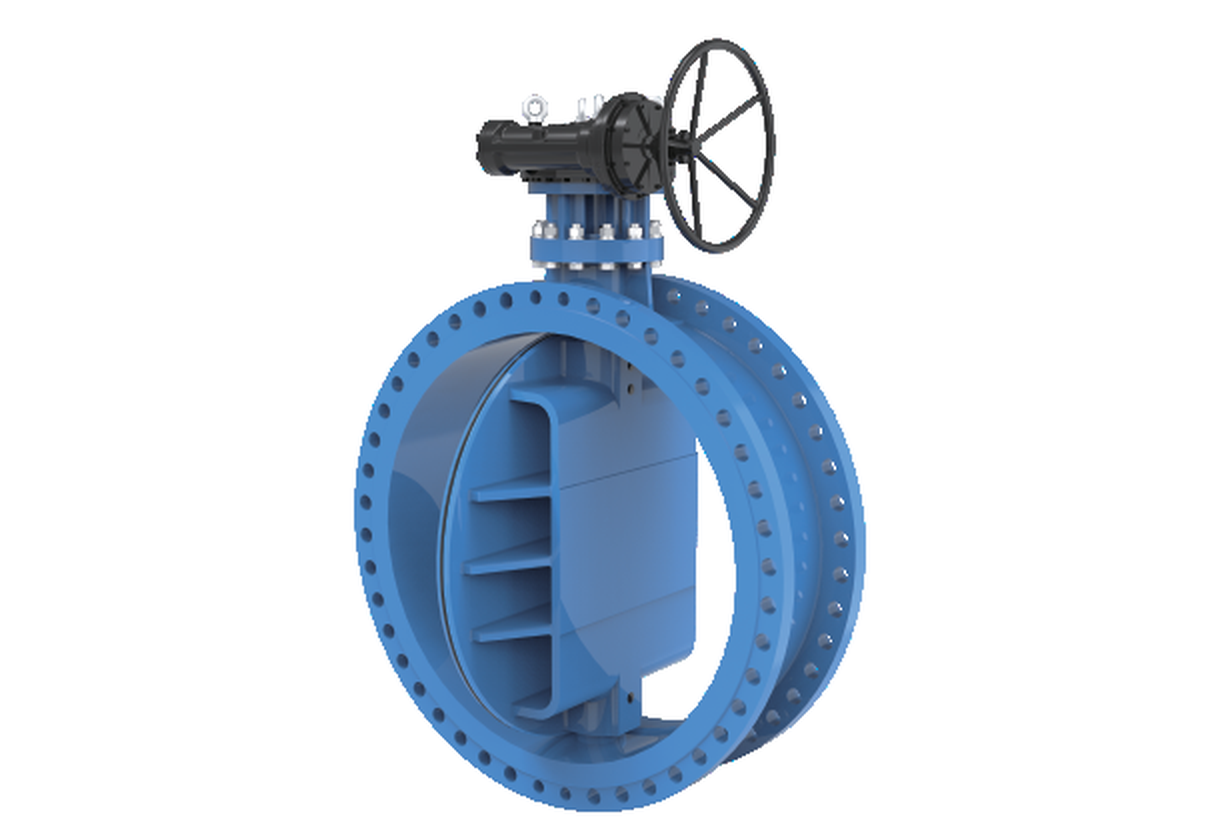

Triple-Offset Valve Highlights

Three‑Offset Geometry: Ensures frictionless cone seal and zero leakage—metal-to-metal construction and fire-safe.

Reliable & Low‑Torque Operation: Bidirectional with easy actuation and simple inline maintenance.

Industrial-Grade Build: Metal seat and components withstand high-pressure, severe conditions.

Specifications at a Glance

| Valve Type | Size (DN) | Pressure Rating | Materials & Connections | Key Benefits |

|---|---|---|---|---|

| Double-Offset | DN50–DN4000 | ASME Class 150–600 | Carbon/Stainless/Alloy/Copper steel; Wafer, Lug, RF | Low torque, compact, reliable |

| Triple-Offset | (typical range) | (consult) | Metal-seated; robust, fire-safe | Zero leakage, high durability |

Applications

Data Centers

Chemical, petrochemical, & refinery systems

High-pressure oil and gas pipelines

Power generation

Adverse or safety-critical industrial environments

Why Choose Double-/Triple-Offset

Double-Offset: Cost-effective, low-torque, durable—great for general industrial use

Triple-Offset: Superior sealing and safety—ideal for critical, high-performance sectors